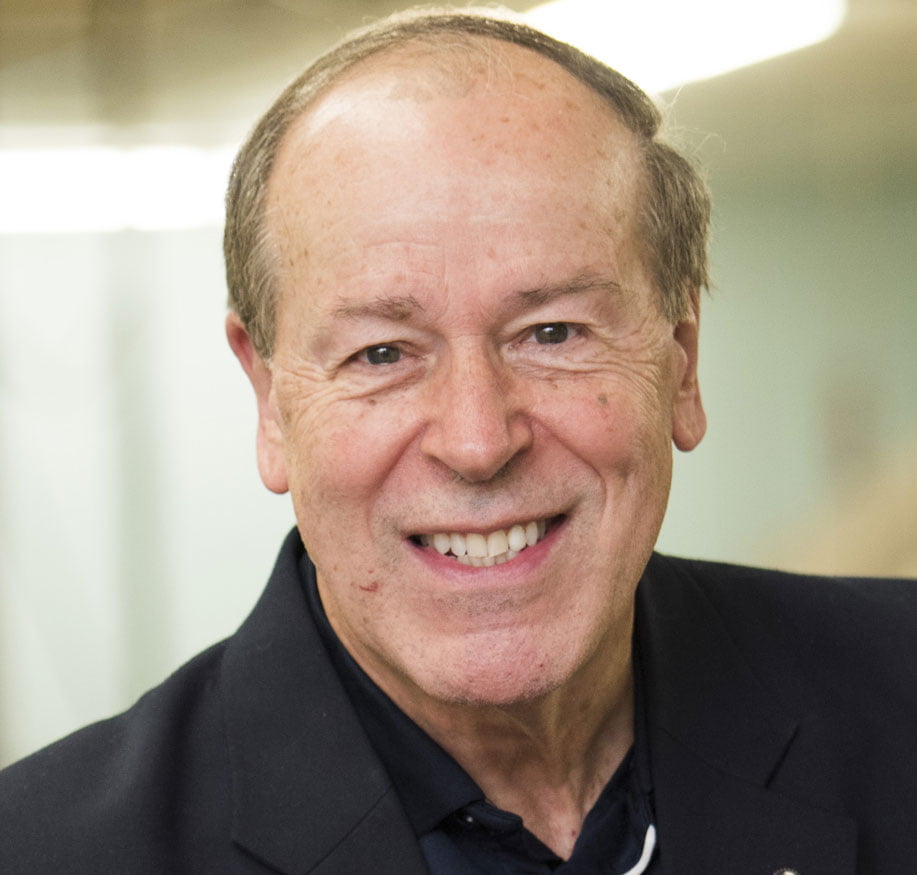

When Dan Pavalnsky came to Hibco Foam Plastics from his position at Dow Chemical, he brought a keen understanding of the science and engineering that goes into producing quality foam products.

In 1979, when he became the owner of Hibco Foam Plastics in Yadkinville, NC, Dan began growing the business into what it is today – a premier foam plastics manufacturer whose responsiveness, creativity, and attention to detail have made it one of the most respected names in the industry.

Today, Dan’s sons, Mark, Keith, Jess, and Chris, manage the sales, manufacturing, and day-to-day operations under Dan’s watchful eye. The Pavlansky brothers, all with engineering backgrounds, navigate the company through the ever-changing waters of the economy and the continually evolving world of foam manufacturing.

throwing our scraps in the landfill. Over 80% of the foam waste we generate is repurposed into new foam products, and we encourage others to follow our lead.

throwing our scraps in the landfill. Over 80% of the foam waste we generate is repurposed into new foam products, and we encourage others to follow our lead.