Hibco is a leading supplier of foam plastics products suited for commercial, industrial, military, manufacturing, and residential applications. We offer a diverse line of manufactured foam products and raw materials for cushion packaging, sealing, seating, building construction, marketing, and more. If you don’t see the product you are looking for, or have a specific need or special request, please contact us.

Sponges

Non-Reticulated Foam is perfect for creating scrubber sponges. We offer customization and private label options unique to your needs.

Ensolite®

Cross-Linked Polyethylene (XLPE) – With its small, uniform closed-cell structure, XLPE is a perfect packaging solution when impact strength and abrasion-resistance matter.

EthaFoam®

EthaFoam® is our go-to when our clients are looking to protect sensitive equipment or fragile items.

Crosslinked High-Density Polyethylene

Crosslinked High-Density Polyethylene foam is as durable as it is versatile for any number of applications. C.I.D. A-A-59135/59136 Compliant.

Polyurethane Foam

Polyurethane foam is unmatched in its versatility, strength, and temperature resistance, making it ideal for packaging and storage solutions.

Our Products / Materials

Anti-Static Polyethylene

- Closed-cell foam with anti-static discharge protection

- Offers controlled, dissipation of electro-static charges emitted from neighboring materials during handling, assembly, and shipping

- Available in rolls or planks

- Ideal for electronics packaging

- Standard color: pink

As shown:

- Die cut

- Heat bonded

Conductive Foam

- Offers electric conductivity and electromagnetic shielding

- Firm and soft formulations available

- Up to 1/2″ thick sheets can be joined together for greater depth

Convoluted Foam

- Produced from open-cell polyurethane foam

- Ideal for packaging, acoustic panels, noise dampening, case inserts, and more

As shown:

- Die cut SCAR pack

Cross-linked High-Density Polyethylene Foam

- Durable closed-cell foam is chemical, water, heat and impact resistant

- Available in 2 to 8 lbs./cu. ft. densities in rolls 1/16″ through 5/8″ thick, and laminated planks

- C.I.D. A-A-59135/59136 compliant

- Ideal for military packaging, GSA packaging, closure strips, gaskets, seals, sports/gymnasium flooring, dunnage, pads, and corner protectors in product packaging

- Standard colors: black, blue, charcoal gray, and mint green

As shown:

- Die cut

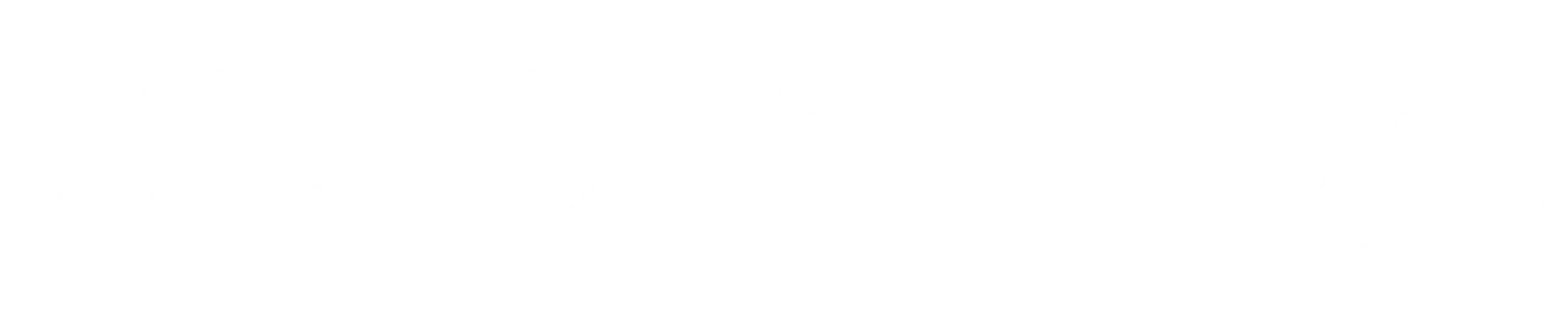

Corrugated Plastic

- Water-resistant polypropylene and polyethylene plastic is bondable to most foams or molded

- Available in various mil. thicknesses

- Bubble-X® is available when greater rigidity is required

- Standard color: black

Dunnage

- Polyethylene foam featuring high energy-absorption properties

- Lightweight, durable, and reusable

- Provides optimal impact and static absorption properties

- Can be fully customized to match most any need

EnsoLite®

- Closed-cell polyvinyl chloride foam made from a blend of PVC and Nitrile Butadiene Rubber (NBR)

- 3.5 to 9.0 lbs. per cu. ft. densities

- Temperature resistance from -20°F to 250°F.

- Applications: industrial gasketing, flotation insulation, and athletic padding

EthaFoam®

- Closed cell foam available in 1.5, 1.8, 2.2, 4, 6, 9 lbs./cu. ft. densities

- Water and chemical-resistant

- Superior energy absorption, vibration dampening, insulation, and buoyancy

- Excellent heat and cold resistant properties

- Standard colors: black, white

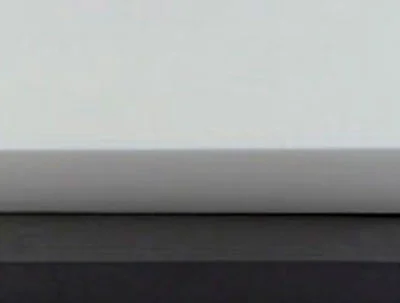

Expanded Polystyrene (EPS) Foam

- High compression strength and easy to mold into shapes

- Available in 1, 1.5, and 2 lbs/cu. ft. densities

- Ideal for blocking and bracing items for shipping

- Standard color: white

Foam Rubber Blends

- Closed cell foam available in densities up to 9 lbs./cu. ft.

- Temperature resistance from -20° to 250° F

- Superior energy absorption, vibration dampening, insulation, and buoyancy

Linear Polyethylene

- Closed cell foam available in low-density planks and rods (1.0 to 2.2 lbs/cu. ft.) and high-density planks (4.0 to 9.0 lbs/cu. ft..)

- Also known as high-density polyethylene — HDPE

- High stress and resistance

As shown:

- Die cut

- Heat bonded

- Routed

MicroCell®

- Chemically cross-linked polyolefin closed cell foam

- Extremely fine cell structure

- Available in 3″ and 4″ bun form

(fire-retardant grade available) - Meets requirements for both Vehicle Safety Standard FMVSS-302 and Aviation F.A.R. 25.853 (A) vertical burn test

- Standard colors: natural, white, gray, charcoal, blue, black, yellow, and green

Polyethylene (PE), Polypropylene (PP), and Expanded Polyethylene Foam

- Polyethylene (PE) and Polypropylene (PP) each has very high compressive strength

- Resilient molded foam ideal for cushion packaging and automotive applications

- Chemically stable, high thermal resistance, and available in a variety of densities

- Water and chemical resistant

- Can withstand multiple impacts

- Bonds well to other foam products

- Water and chemical resistant

As shown (PE):

- Die cut

- Heat bonded

Polyethylene Roll

- Available in 1/32” to 1/2” thickness and 0.9 to 4.0/cu. ft. density

- Available in anti-static

- Moisture resistant

Polyether Urethane Foam

- High resilience open-cell flexible foam can be formulated to meet the MIL-PRF-26514, Cal-117, MVSS302, UL-94, and the FAR 25.853(a) specifications

- Available in 0.9 to 4.0 lbs./cu. ft. densities

- Use for protective packaging, automotive, sports, leisure, aerospace, marine, construction, military, case inserts, medical, appliance, filters, gaskets, displays, etc

Polyurethane Foam

- Ideal for sound and heat insulation

- Reacts rapidly in humidity and expands when exposed

- Bonds well to multiple surfaces

As shown:

Pin needle convoluted

Reticulated (Filter) Foam

- Available in 5 ppi (pores per inch) to 100 ppi

- Ideal for air filtration in multiple applications as well as for scrubbing pads, and gutter filtration

As shown:

- Dual-foam sponge/scrubber

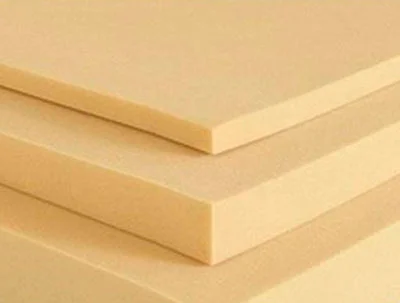

Rigid Polyurethane High-Density Foam

- Ideal for insulation in temperature ranges from -65° F to 250° F

- Available in 1.6 to 20 lbs./cu. ft. densities

- Used for architectural models, specialty high-strength areas, Structural applications

- Can be nailed, screwed, glued, bolted, and stapled directly into foam

- Impervious to solvents and waterproof

- High or low temps, rain, snow, ice, or frequent sprinkler waterings have no effect

Softlon® Opencell Foam (Sekisui)

- Flame-retardant open cell foam in 3, 5, 7, 10, 15, and 20 mm thickness

- Available with skin on both sides, or skin and skived sides

- Adhesive coating optional

Styrofoam® BB

- Buoyancy billet (BB) extruded polystyrene in 1.8 lbs./cu. ft. density

- Water and microbe-resistant

- Standard color: blue

Styrofoam® HL (Highload) Foam Insulation

- Extruded polystyrene for use as load-bearing insulation

- HL100 insulation has 100 psi (690 kPa)

- Comes in planks (typical size: 2” x 48” x 96”)

- Standard color: blue

Styrofoam® Panel Core SE & TG

- Extruded closed-cell polystyrene foam for thermal insulation with high water-repellent properties and superior bonding surface

- 1.9 lbs./cu. ft. density

- Superior bonding surface

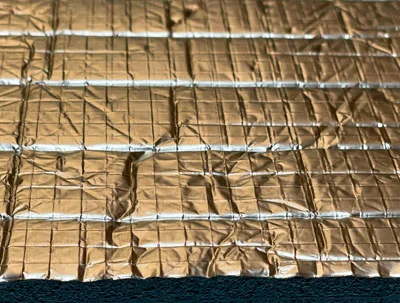

Thermobreak™ Thermal Insulation (Sekisui)

- Cross-linked closed-cell polyolefin foam offers flexible thermal insulation

- Factory-bonded aluminum foil

- Almost zero vapor permeability

Volara® (Sekisui)

- Closed-cell irradiated cross-linked polyolefin foam is highly water and chemical resistant

- Available in rolls or sheets

- Standard color: black

VolaraBLOCK® (Sekisui)

- Laminated Volara® up to 4” thick

- Closed-cell irradiated cross-linked polyolefin foam is highly water and chemical resistant

- Standard color: black

Volextra®

- Abrasion, chemical, and water-resistant foam with flexible coating in optional patterns

- Solid plastic is permanently melt-bonded to Volara® foam