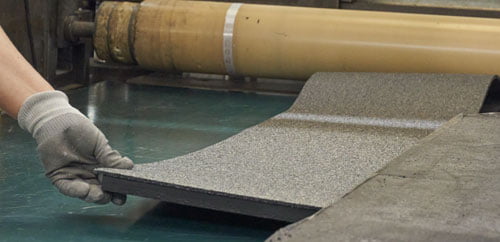

Hibco is a leading supplier of foam plastics products suited for commercial, industrial, military, manufacturing, and residential applications.

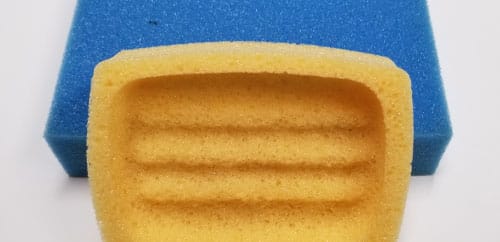

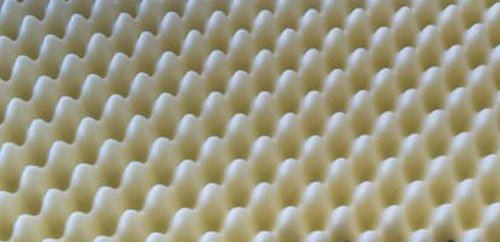

We offer a diverse line of manufactured foam products and raw materials for cushion packaging, sealing, seating, construction, marketing, and more. If you don’t see the product you are looking for or have a specific need or special request, please contact us.